Enhanced driver vision via powerconsumption-less technological solution

Result from partners LIST and TME.

Result has been achieved in April 2020 : month 30 of the project.

Short introduction

Windshield and view mirrors fogging-up is a common issue met by every driver, who’s vision can be seriously hindered, creating a safety risk if not mitigated. To counteract fogging, the in-vehicle heating and air-conditioning systems can be used to heat the glass surface and prevent fogging. However, this traditionnal use of active systems is responsible for an increase of the power consumption. For Battery Electric Vehicles (BEV) and Hybrid-Electric vehicles (HEV), this leads to a reduction in available energy to propel the vehicle, thus reducing the range of the vehicle.

Objective

This research for the DOMUS project aimed at developing a permanent -electric consumptionless – anti-fogging coating solution for windshields, using a scalable, efficient and cost-effective atmospheric-pressure plasma-enhanced chemical vapour deposition (PECVD) process.

Research

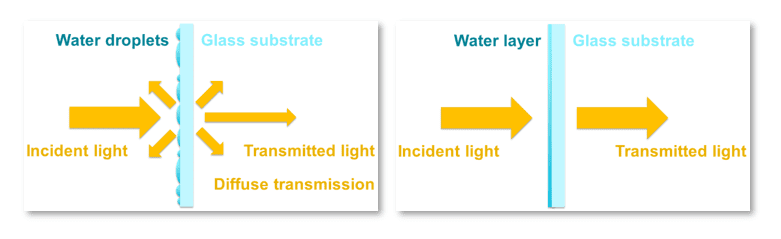

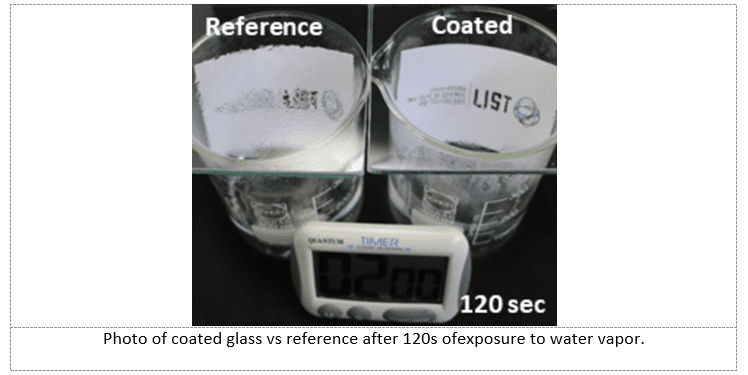

The approach proposed by LIST is based on the principle of keeping the light transmission through the windshield despite the condensation of water vapor present inside the car, thanks to a finishing superhydrophylic surface treatment. The high surface energy of superhydrophilic surfaces promotes the spreading of water (i.e. overcoming the water surface tension and allowing the water droplets to merge) and the formation of a thin and invisible water layer (right), significantly improving the driver’s vision.

The selection of a PECVD process was motivated by the characteristic of such techniques to be operated under atmospheric-pressure conditions as a finishing surface treatment, which is important in the perspective of automotive applications, and at low-temperature, which is essential to preserve the integrity and optical performances of the windshield.

What was the result?

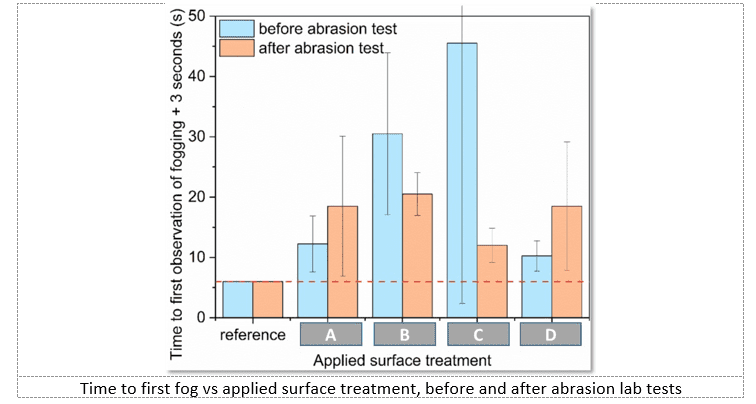

Two approaches have been investigated at the Luxembourg Institute of Science and Technology (LIST) and characterized in collaboration with Toyota Motor Europe (TME).

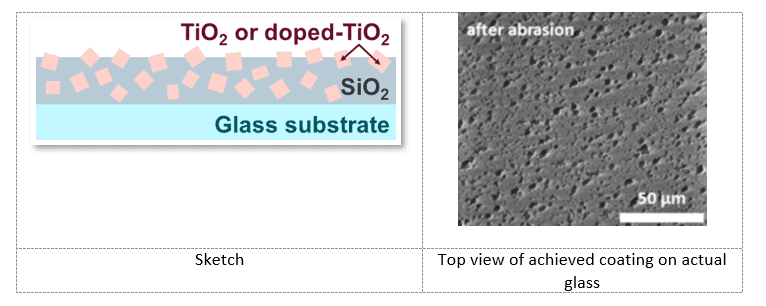

The first one relies on nanostructured TiO2@SiO2 nanocomposite thin films, which revealed to be quite relevant to be implemented on the inner side of headlamps or detectors lenses.

The second approach, where the coating architecture was redesigned as doped-TiO2 single layer to meet all the requirements for anti-fogging windshield applications, as tested at lab scale.

What will the results be used for?

The most suitable deposition conditions identified on laboratory-scale samples within the research on windshields that will be assembled and tested at the full demo vehicle level at TME in the framework of Result category 6. Separate test will be done on a TOYOTA CHR demo vehicle. The results of these tests will be transferred to the overall efficiency assessment of the FIAT 500e.

What is the impact?

The TOYOTA CHR demo vehicle will allow for a vivid estimation of the impact of the technological that has been developed here. We are eager to reach that step!