The Development of an Efficient Thermal Cabin Model with Computational Fluid Dynamic (CFD) Simulation

Result from partners COV and CRF.

Result has been achieved in April 2020 : month 30 of the project.

Short introduction

Computer aided engineering (CAE) and design has revolutionised car manufacturing as it offers performance insight during the development stage, manages risks, and resolves challenging real-life design problems. However, the use of CAE is not without limitations, as there is a degree of tension between the need for accuracy and the computational speed required to optimise a system with multiply variables and complex systems within a reasonable time. For example, machine learning approaches that learn control algorithms such as Reinforcement Learning tend to require months or even years of simulation time to converge to the optimal solution. Therefore, when approaching the simulation model to improve the design of the cabin comfort, DOMUS seeks to explore the possibility of a thermal cabin simulation model that could not only virtually assess cabin comfort but could also be far more rapid in response without compromising accuracy.

Objective

DOMUS has produced a high accuracy simulation (see Report 1.5) using computational fluid dynamic (CFD) simulation, which takes around 10 minutes (elapsed time) to compute one second of transient simulation but ideally requires a much faster simulation. This cabin model will be supported by a holistic cabin comfort model and an assessment framework to assess the comfort and efficiency of any solution. However, the assessment framework is based on the simulation of 28 different scenarios that vary in length between 10 minutes to 30 minutes. As the total simulation time for a single assessment is considerable, researchers at Coventry University and CRF were tasked to find ways to resolve the tension between high accuracy simulation and the computational speed required for full optimisation when looking at thermal comfort.

They began by asking the following questions:

- To what degree can machine learning be used to approximate high accuracy simulation?

- To what level is a simulation needed to perform optimisation on such things as the HVAC control algorithm?

Research

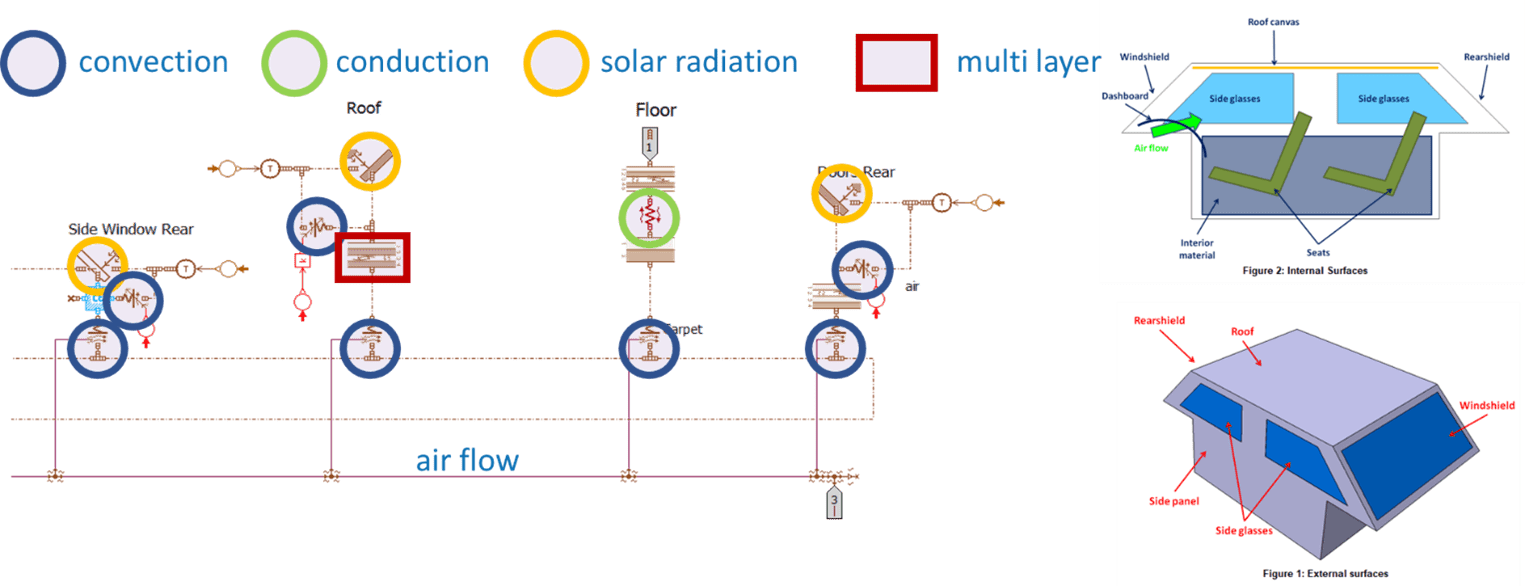

This led them to produce a machine-learnt thermal cabin simulation and a 0D thermal cabin simulation model of the thermal aspects of the car cabin. By 0D cabin model, the researchers sought a model that is based on ‘lumped thermal capacity’ that uses simplifying assumptions to produce approximate but reasonably fast thermal simulation.

Producing a 0D model has two key functions. First, to compare and contrast accuracy to see to what extent the machine learnt simulation is at least comparable or better than the 0D simulator in terms of accuracy and computational speed. Second, the 0D cabin model provides a back-up plan in case the machine-learnt approach fails.

Methods

- The 0D modelling of the car cabin used AMESIM

- Machine learning works by finding a mapping from the last two state and control vectors into the subsequent state vector.

The cabin model is just one of the subsystems of the complete conditioning model of the vehicle. The other subsystem are the AC Loop and the HVAC module. The two models were compared in terms of their accuracy against the CFD simulation provided in D1.4, available measurement data produced in a climatic wind tunnel and in terms of simulation performance on roughly equivalent computational hardware.

Result

The results are as follows:

- The machine learnt cabin model has an average normalized RMSE over all sensors of 1.8%. The RMSE for the average air temperature for the front bench is 0.4 K (0.8%) over all trials.

- Machine learnt cabin model computes a second of simulation time in 5.44 × 10−6

- The machine learnt cabin model is able to interface to the holistic comfort model and, in comparison with the CWT data, gives a misclassification rate that ranges from 1.3% to 3.4%.

- The 0D cabin model predicts the cabin average air temperature within ± 1 K (1.52%) with respect to the reference temperature.

- The 0D cabin model predicts AC pressure with an average error less than 0.6 bar (3%) at high pressure and 0.1 bar (6%) (steady state) at low pressure

- The 0D cabin model computes a second of simulation time in 0.25 s (worst case – when the AC compressor is on) or 0.0076 s (AC compressor off).

The idea of using machine learnt models for simulation is not new. But these findings are significant because in providing a simulation using machine learning and comparing it to a 0D model it shows the potential that machine learnt simulation models offer in car manufacturing when high accuracy simulation is required. By rethinking our approach to simulation, by learning the simulation from experience data, we can provide a simulation that is both more accurate and computationally much faster than traditional approaches.

What is the impact?

The impact of these results goes beyond the aims and objectives of the DOMUS project. By understanding and applying artificial intelligence to provide faster simulations of nuanced and diverse human actions could alter the way cabin car simulations are produced. In the long term, this could encourage the adoption of a machine-learnt experience-based approach to design in the automotive sector and, indeed, many other industries.

Bottom-up approach: from the component level to the system

0D Lumped parameter model for the cabin